Orthopedic foot scanners for more comfort and patient satisfaction

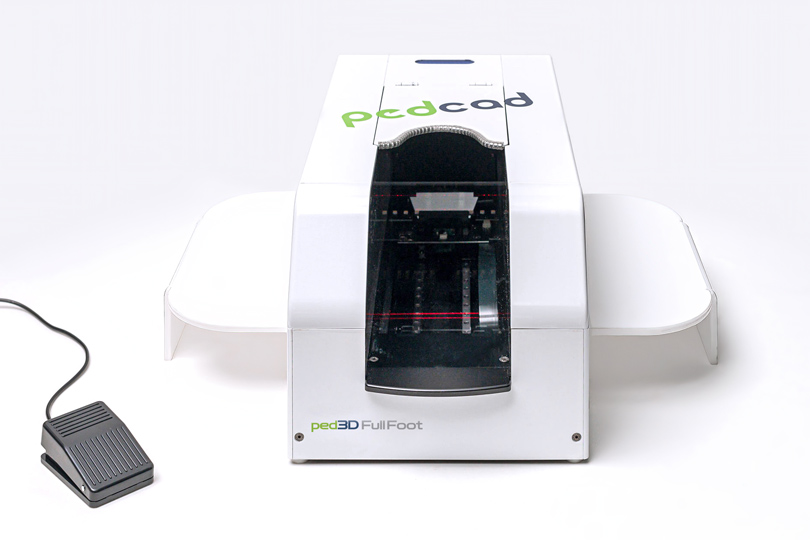

Laser foot scanner ped3D Full Foot

Medical supply stores and orthopedists usually aim to effectively treat and relieve existing foot problems of their patients. Orthopedic insoles as well as custom-made shoes and orthotics are designed to provide patients with maximum comfort and to counteract secondary diseases.

An elementary basic condition for effective treatment is the exact measurement of the feet, taking into account the underlying indications. If the measurement of the feet is done correctly, you as an employee of a medical supply store can have a lasting impact on the lives of your patients and help them to walk, run and move comfortably. And they can do so without being limited by pain or discomfort.

Today, orthotists use a wide variety of procedures and technologies to take the most accurate foot measurements possible. The most modern and advanced foot scanning technology is the 3D Full Foot scanner. In this article, we would like to introduce you to this technology so that you can offer your patients more quality of life and freedom of movement.

The most important facts in a nutshell:

- Orthopedic foot scanners, like the ped3D Full Foot-Laser Scanner, are technologically advanced and take millimeter-precise foot measurements for the prevention and treatment of foot diseases possible.

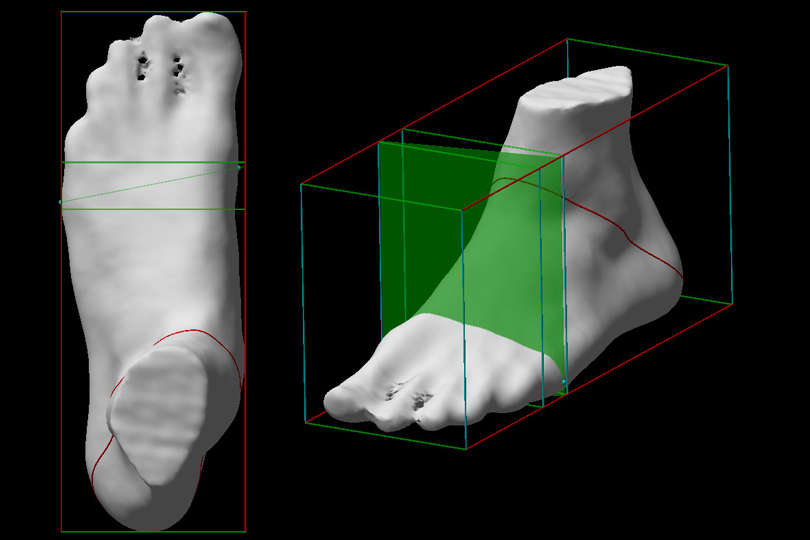

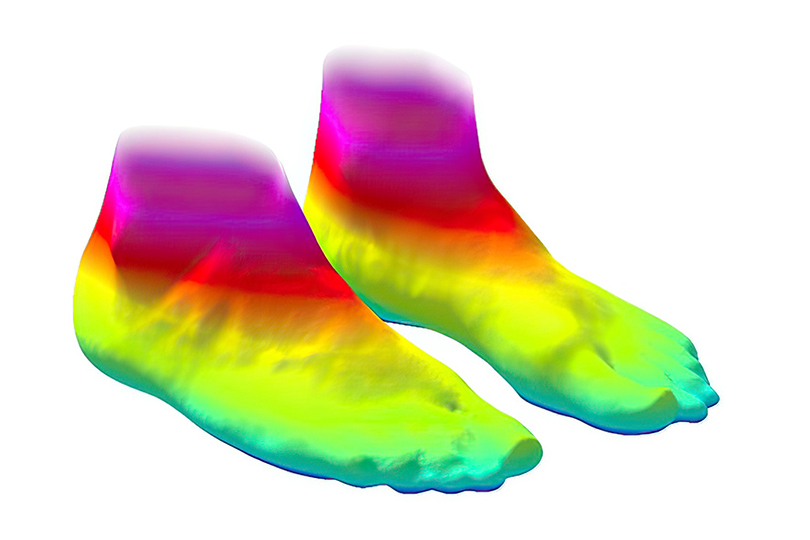

- The ped3D Full Foot by pedcad offers you high-quality 3D scans as well as a 2D scan in grayscale for direct processing of the measurement data.

- The powerful pedoffice management software allows a central data management of different measuring devices in one place. In addition, the scan data can be prepared for further processing. Order management is largely automated.

State-of-the-art foot measurement methods for more detailed measurement results

In addition to numerous other foot measurement methods such as ⇢ 2D foot scanners and plantar ⇢ 3D foot scanners, many medical supply stores now rely on the new ⇢ full foot scan technology.

Advantages of Full Foot scanners for the creation of orthopedic insoles

Modern laser foot scanners such as the ped3D Full Foot capture, scan and digitize the entire foot with millimeter precision in just a few seconds. Full Foot scanners are not considered highly precise for nothing, as they offer a level of detail that is almost impossible to achieve with other methods of measuring the foot.

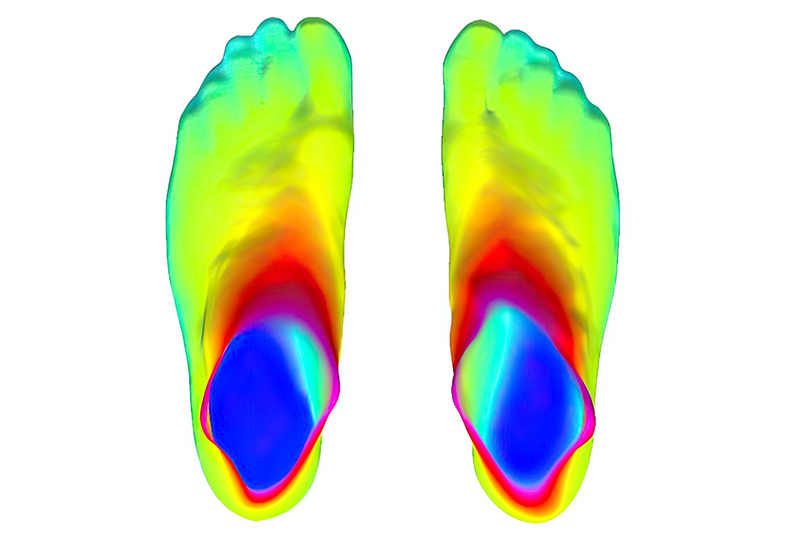

With the aid of special ⇢ software, the measurement data obtained can be viewed immediately and used to design high-quality insoles that are optimally tailored to the patient's individual needs. This is especially useful for medical professionals when assessing and treating foot disorders and creating custom-fit aids.

Consequently, as a medical supply store, you benefit from such an orthopedic foot scanner compared to other methods by being able to take more precise measurements on the patient and thus provide your customers with better-tailored aids.

learn more

The universal talent for creating orthopedic custom shoes and orthotics

The Full-Foot scanner is particularly attractive for use in medical supply stores or P&Os because it proves to be a true universal talent that can be used in various areas of fitting. Whether insoles, orthotics or orthopedic custom shoes are the target of care is completely open.

The Full Foot Foot scanner is particularly suitable for collecting the measurement results required for the manufacture of customized shoes, as results such as ball, instep and heel measurements, as well as a wide range of other information, can be transferred directly to the manufacture of individual shoe lasts and orthoses. The determination of these measurements is fully automated at the push of a button. This not only makes the measurements reproducible, independent of the user, it is also many times faster and cleaner than collecting data with a cast or tape measure and pencil. The data format of the orthopedic foot scanner is suitable for last design in CAD programs in-house or at the manufacturing service provider.

The orthopedic foot scanner ped3D Full Foot by pedcad

Digital foot measurement made easy.

With state-of-the-art technology, pedcad's ped3D Full Foot offers you not only the possibility to perform detailed 3D scans, but also the option to create static measurements or digital 2D representations of the sole of the foot. Due to its compact size and its low weight of only 10 kilograms, our orthopedic foot scanning device is mobile and transportable at any time. For use in your own measuring rooms, the scanner can also be permanently installed in a piece of furniture and discreetly integrated into the premises - we would be happy to advise you in this regard when planning your practice.

The measurement data can be output in JPG and STL or WRL format, which makes it easy for you to process the data. An integrated exposure correction ensures ideal scan images. The report is available as a PDF with color representation and optional 1:1 view of the foot measurement. The scanning speed of the orthopedic foot scanner is approx. 3.2 seconds.

-

Advantages:

- inexpensive entry-level variant

- mobile use and transportable

- also suitable for fixed installation

- compact dimensions

- easy handling

- creates 2D and 3D scans

- STL output data

-

... and of course all of our measuring systems can also be combined with one another.

In our insole construction software ⇢ InsoleDesigner Several measurements can even be superimposed in order to use the optimum of all measurement types.

-

Features:

Measurement:

- static measurement

- 3D scan of the whole foot

- 2D scan of the sole of the foot in grayscale

Application:

- mobile or fixed

Report:

- PDF report

- color representation of the foot measurement

- optional 1: 1 view of the foot measurement true-to-scale export for further digital processing

Software:

- pedoffice or pedoffice light

System requirements PC:

- Windows 10, 11

- CPU: i5-6200U

- RAM: 8GB

Measurement data:

- STL / WRL

- JPG

Scanning capabilities:

- Foot

- Bars

Dimensions:

- 520 x 270 x 220 mm

Weight:

- 10 kg

Measurement volume:

- 330 x 130 x 120 mm

Speed:

- 3.2 sec.

Accuracy:

- +/- 1 mm

Power supply:

- power cord 120-240V; 50/60Hz worldwide

Included:

- Power adapter, USB cable, foot switch, step elevation, scan mode with exposure correction and pedoffice Lite software.

Direct further processing of the measurement data

Once the foot scan has been completed, you as the user can then easily process the digital image to scale using our software solutions for the detailed creation of the insole, including size adjustment and free modeling. The software can also be used to save, mill or print a dimensionally accurate foot last, insole or even as a basis for designing orthotics.

In this way, our orthopedic Full Foot scanner helps you improve your presence and competence at the customer and gain a significant time advantage in production.

pedoffice –

the variable management software for foot scans

The pedcad software systems, which can be individually combined with each other, offer you a wide range of management and design options for the production of insoles, orthopedic custom shoes or orthoses for your customers after the completion of your scan.

Our powerful pedoffice management software allows you to further process the measurement data and gives you options for managing your customer data, insole types and materials. All measurement data acquired by you with the 3D scanner can be processed and archived here easily, quickly and intuitively. Our insole design software also allows you, for example, to overlay several foot measurements in order to achieve the best result for your customers and to manage the results of the different measuring devices in one central location.

In this way, the interaction of our orthopedic 3D foot scanner and our pedoffice software increases your presence and competence at the customer and gives you a significant time advantage in the production of your custom-fit aids.

Interested?

Do not hesitate and get in touch with us. We will gladly advise you.

contact now